In the past, cannabis had long been produced solely for regular, dried, and cured flower harvests. As more people turn to cannabis farms for both medicinal and recreational plant sources, the majority of these farms have embraced, at least in part, a new approach. From setting aside a set proportion to converting an entire harvest, farmers are embracing the more dependable method of freezing to keep up with consumer trends and demand, and cut back on costs.

Meeting Demand

As the legality of cannabis use is on the rise in states across the US, innovative consumption methods have also burst onto the scene. While regular joints made from straight plant flowers are a mainstay, many consumers are seeking more pure, potent, and nuanced alternatives. Products from fresh frozen crops can cater to these tastes, while also being compatible with easy-to-use devices that do not create as much odor as traditional joints.

To have quality concentrates and extracts to use such modern accouterments, plants must maintain and preserve their natural properties, like potent THC. The crucial first step in making quality products is sourcing cannabis from fresh frozen harvests, picked at their peak richness and potency and quickly preserved to retain these qualities.

Cost Considerations

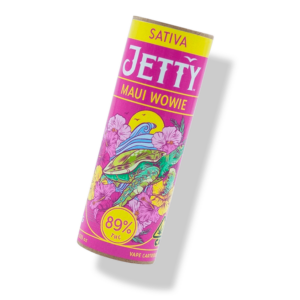

Fresh freezing benefits cannabis farming businesses by reducing labor, risk, time, and money. Efficiency is promoted by significantly reducing labor and time spent on harvesting and monitoring regular drying periods. Using this method for picking and preserving marijuana and efficiently retaining crops that will eventually become products like solventless vape rosin in California, allows farmers to keep up with the market competition. The end goal is to profit from selling to market partners, providing high-quality natural resources for use in making effective and satisfactory treatments and recreational aids.

The Method Difference

More traditional methods of marijuana farming in the Northern Hemisphere involve planting in the spring and harvesting in the fall when plant flower buds are at their ripest and most potent. This method produces plants suitable for conventional smoking, following the long-held tradition of drying in a stable, indoor environment, with many farmers choosing to prolong the process by curing. Curing can be completed in as little as a few weeks to a few months, depending on the desired outcome, specialized taste, and aroma.

Many farmers, however, have noted that this process also incurs several risks, including temperature and humidity variability, which can lead to destructive fungi and mold growth. The harvested plants’ cannabinoid properties also tend to degrade throughout the process, with oxidation especially taking a serious toll on terpene content. Overall, traditional methods can be more of a challenge to preserve the beneficial cannabinoids and terpenes.

For fresh frozen cannabis, all leaves, branches, and stems are removed. The remaining freshly-picked buds or flowers, harvested before they can produce seeds, are vacuum-sealed and packed. Then, the plant packages are stored in a controlled industrial freezer at extremely low temperatures to preserve all moisture, aromas, flavors, terpenes, and cannabinoids before being shipped to the relevant industry partners for extraction. Agricultural producers and potential customers can benefit, since properly fresh frozen plants set aside right after picking will have a longer shelf life, perfect for producing popular products such as solventless vape in California.

Turning Plants into an Experience

When it comes to extraction, industry professionals can employ various methods. After grinding, some places use chemical solvents to blast through the previously frozen buds. This causes the water content to crystallize separately and sets aside all the desired cannabinoids, like THC and terpenes. The solvent then must be removed from the resulting product. What remains is a thick liquid, known for its superior strength to flower alone, at about five times greater potency.

However, many questions and concerns have been raised about the safety of using potentially toxic solvents, with many customers seeking out products specifically labeled as solventless in California. As a result, methods have been developed to offer certain products, like solventless vape rosin in California, without using chemical components, such as ethanol, butane, carbon dioxide, or propane.

To perform this alternative cannabis extraction, establishments separate the valuable trichomes where the majority of the plant resin is found. This is made possible by applying varying combinations of pressure, heat, ice, and water. These innovative methods are beneficial for the producer and are an investment in consumers and the environment. The processes guaranteed to be solventless in California include:

- Considered safer for the environment

- Non-flammable

- Less costly, especially for smaller enterprises

- Simpler, as far as waste disposal requirements

- Of a higher quality and containing fewer impurities

Product Possibilities

The most popular product produced from fresh frozen plants is live resin. This is essentially the driving force behind the demand for fresh frozen quality, as it allows users to benefit from all of the compounds while also enjoying an enticing aroma that isn’t overpowering or stereotypically “pot-like.” Apart from vaping devices, live resin can be used in highly potent dabbing methods produced from high-heat devices like nails and dab rings. Some may choose to add live resin to a regular joint, and some products are available to infuse pre-made products, like joints, for customers ahead of time. On the other hand, products like solventless vape in California require rosin, which is essentially resin that has not been processed with solvents. Rosin can be used in all the same forms as resin, though.

While they are popular, resin and rosin are not the only possibilities. Fresh frozen harvests are also responsible for providing the majority of concentrated resources to make modern products infused with THC. These include gummies, candy, tinctures, food, drinks, and topical applications.